Crude oil and petroleum products metering system

Crude oil and petroleum products metering system

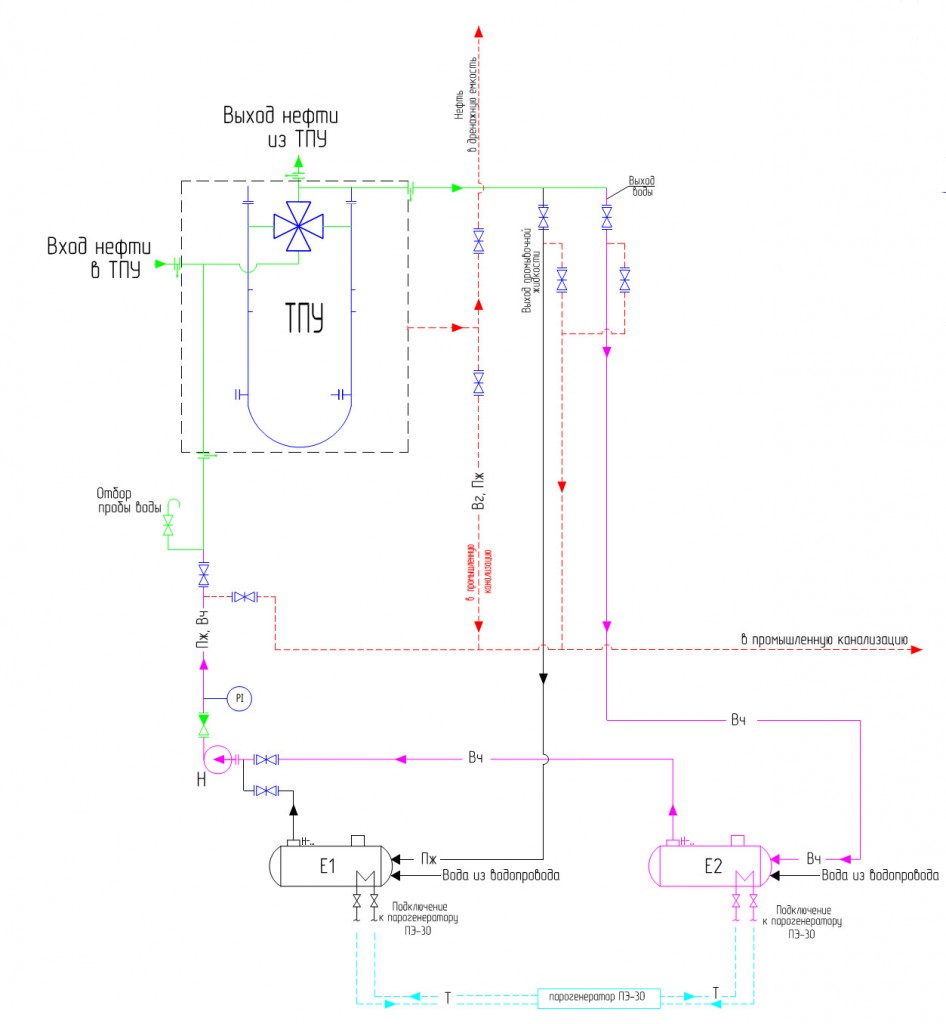

Lease Automatic Custody Transfer (LACT) unit components:

- Process system:

-Meter run;

-Sampler system;

-Meter Prover or connecting assembly for Mobile Meter Prover;

- Process control and data acquisition system;

- Power distribution system.

LACT unit is designed for automatic unattended measurement of gross weight, calculation of net weight and quality metering of oil and petroleum products, indication and logging of measurements results against standards and references applicable for delivery and acceptance operations.

Custom fabrication of LACT units that comprise customer specific features and components is also available.

LACT unit application:

- Automatic unattended measurement of gross weight and calculation of net weight oil and petroleum products;

- Automatic process measurements;

- Automatic quality metering of oil and petroleum products;

- Combined sampling;

- Indication, logging and backing up the measurements results

- Calibration of standard and operational instruments onsite avoiding the violation of measurements procedure;

- Control of metrological performance of the instruments onsite avoiding the violation of measurements procedure;

- Data transfer to upper level.

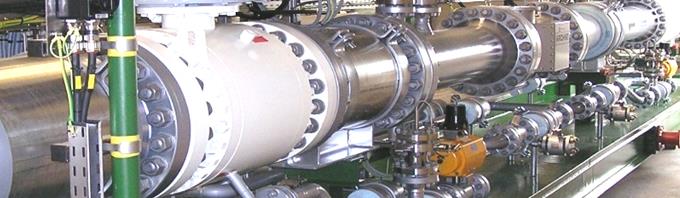

Meter run

Standard Meter Run components:

- Inlet and outlet header;

- Meter Prover header;

- Operating, backup and control(backup control) instrumentation lines;

- Drainage system.

LACT unit is designed considering the operating flowrate and product quality parameter values basing on the different flow meters.

Draining of both metered and unmetered oil within the Meter Run skid is maintained with separate headers, each equipped with drain valves complete with leakage control system.

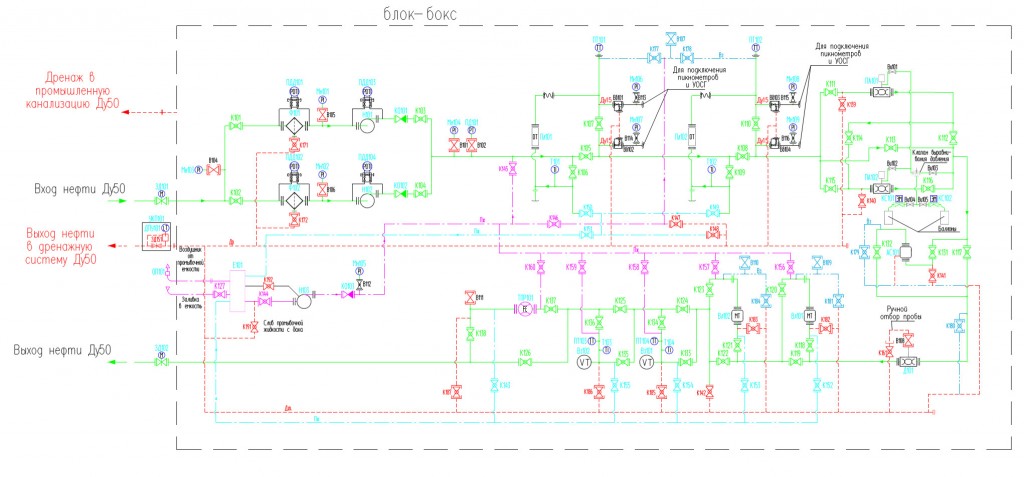

Sampler system

Meter Run is incorporated in the custody transfer and fiscal metering systems that Magna Engineering develops according to standard and custom fabrication designs.

Oil, subjected to Sampler system, is collected from reservoir with sampler. Target Sampler system flowrate value is maintained with calculations specified in design documentation. Sampler system flowrate is either controlled with electrically or manually driven regulator, or with centrifugal pump complete with rpm control. Target flowrate value control is maintained with flow meter complete with remote or local indication.

Sampler system is located within a separate heated block-box comprising piping complete with oil quality instruments. Block-boxes are equipped with explosion proof lighting fixtures and electric heaters, internal automatic gas detection system, audio and visual fire alarm, balanced ventilation.

Application: Sampler systems comprise oil quality instruments, sampler and other appliances. Usually Sampler system is installed bypassing the main LACT unit pipeline (header) and only part of the product flow is subjected to Sampler system.

Sampler system components and design depends on the type of flow meters and list of product quality parameters applied and may comprise as follows: density and viscosity meter, pressure and temperature transmitters, pressure and temperature gage, automatic and manual samplers, flow meters, centrifugal pumps, sulfur analyzer, salt analyzer, moisture analyzer, free-gas volume detection device, as well as connecting assemblies for pycnometer.

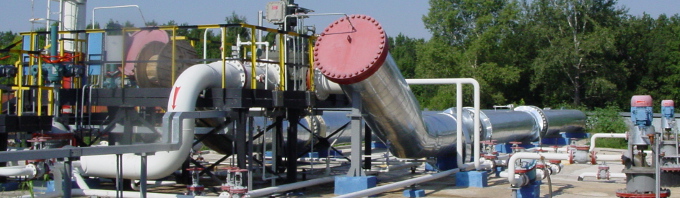

Meter prover

Standard Meter Prover components:

- Access platforms for maintenance of launch/receive chambers and four-way diverter valve;

- Closed drainage system complete with leakage control system for the valves branched in the upstream and downstream piping outside the prover loop;

- Interconnecting nozzles for prover flush system and standard calibration rig basing on the prover tanks.

Range of Meter Prover flowrates complies with operating range of the flow meters installed within Meter Run. Maximum operating pressure of Meter Prover complies with maximum operating pressure of LACT unit.

Process control and data acquisition system

Standard components independent of LACT unit process solutions:

- Instrumentation box ;

- PLC box;

- Secondary equipment box;

- Emergency protection and alarm box;

- Communication board;

- HMI Work station of LACT unit operator(main);

- HMI Work station of LACT unit operator(back up).

Secondary equipment and PLC may be installed within 1 enclosure box.